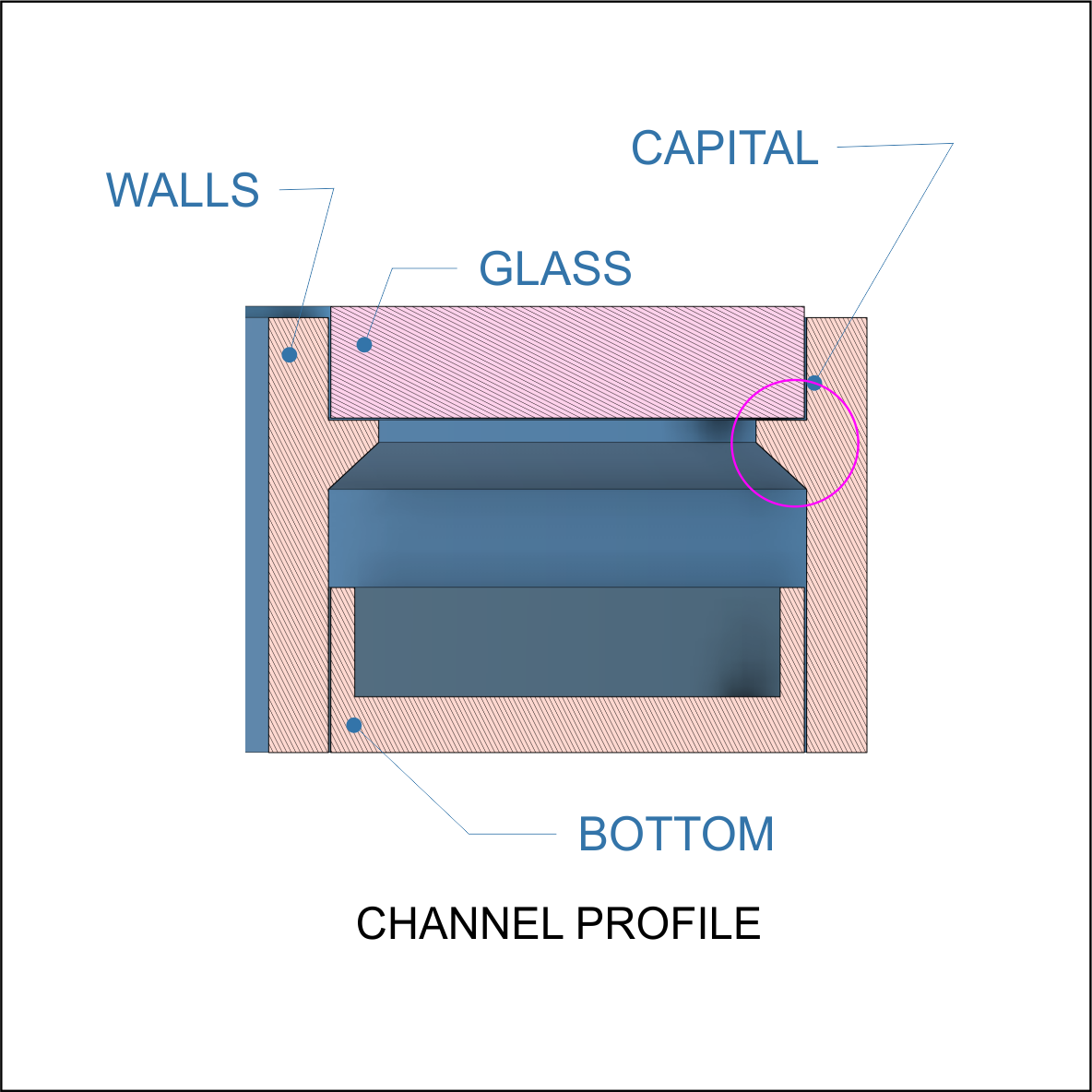

Channel profile is a section through all components of the channel letter sign.

GLASS – the name stands for the front face of the channel letter. It is usually made of translucent material like acrylic. It can be cut by a laser cutter or router or manufactured by a 3D printer.

WALLS – create the depth of the channel letter and a place for the light sources. The part to be created by additive manufacturing.

CAPITAL – creates support for the GLASS. The name of this part is inspired by the name of the topmost part of a column.

BOTTOM – is the part that closes the channel profile. This part connects the channel letter to a supporting structure (e.g., wall, metal mesh, or a construction).

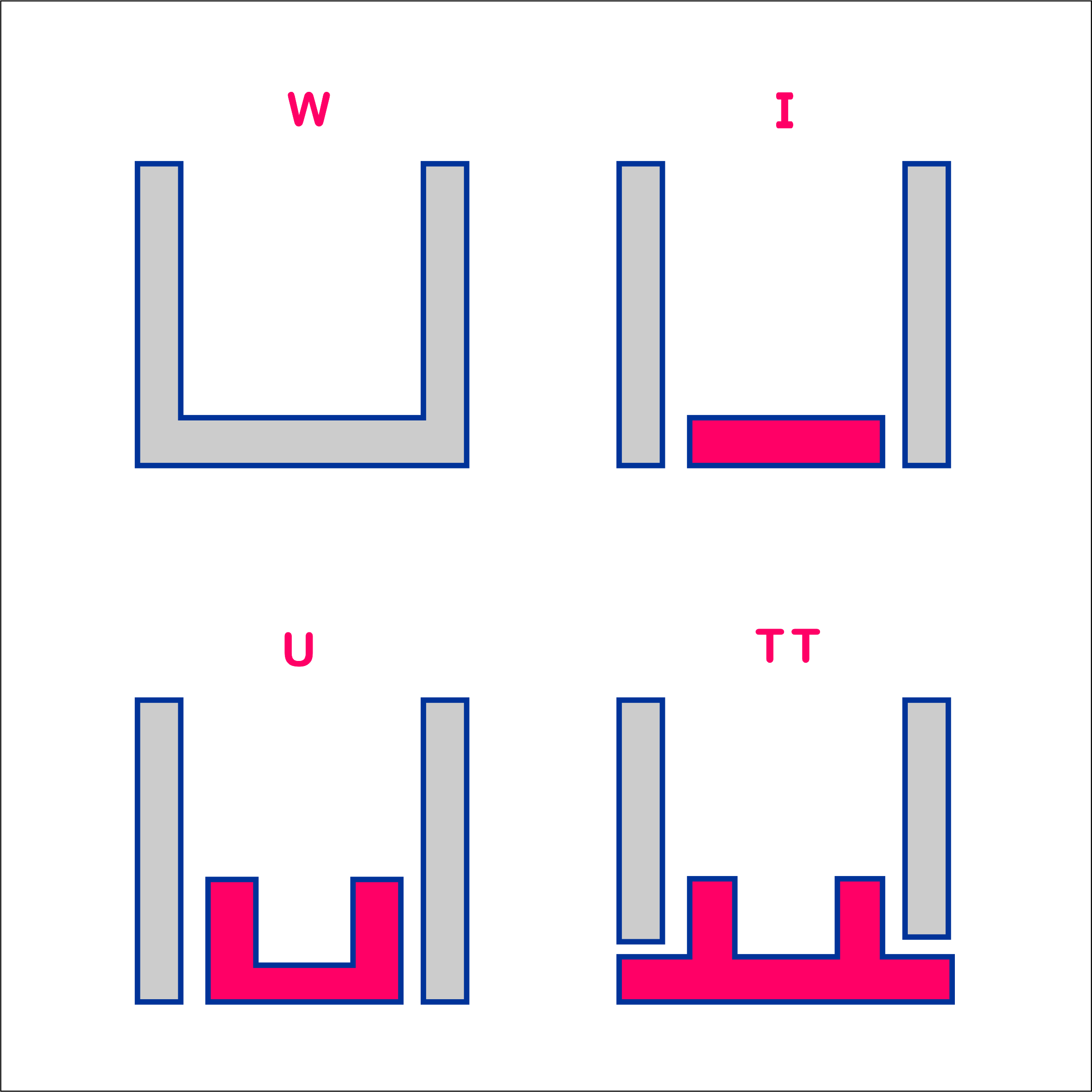

You can choose from multiple types of BOTTOMs.

W – type (as welded) is the only profile that is integrated with the WALLS.

Together with WALLS, create a U-shaped profile. The whole structure has to be 3D printed.

I – type is a flat profile that copies the shape of the glyph profile and GLASS. The WALLS fully cover the bottom profile and, therefore, it isn’t visible after assembly.

U – type is a bottom profile with sidewalls. WALLS fully cover the bottom.

The bottom with sidewalls can be made from more reflective material (e.g., white filament) if WALLS are dark, less reflective color.

U-type also strengthens the construction of the channel.

TT-type – it is similar to U-type with the bottom extending under the walls. The bottom base is visible if made from different materials. It is recommended to use this type if the sign isn’t mounted on a flat surface.